To troubleshoot your pressure pool cleaner, start by checking the water pressure and flow rate to make certain it’s within the recommended range. Examine hoses, fittings, and brushes for damage or blockages, and make sure everything is properly installed and positioned. Clean filters and skimmer baskets regularly, and adjust the pressure regulator if needed. Replacing worn parts and inspecting for mechanical issues can also improve performance. Keep up with routine maintenance to prevent problems; more tips will help you keep it running smoothly.

Key Takeaways

- Check and maintain water pressure within 30-50 psi, adjusting valves as needed.

- Inspect, clean, and replace hoses, seals, brushes, and mechanical parts regularly.

- Ensure proper installation, positioning, and unobstructed water flow for optimal coverage.

- Perform routine maintenance on filters, baskets, and system components to prevent clogs.

- Troubleshoot leaks, worn parts, or blockages, and replace damaged components promptly.

Checking the Water Pressure and Flow Rate

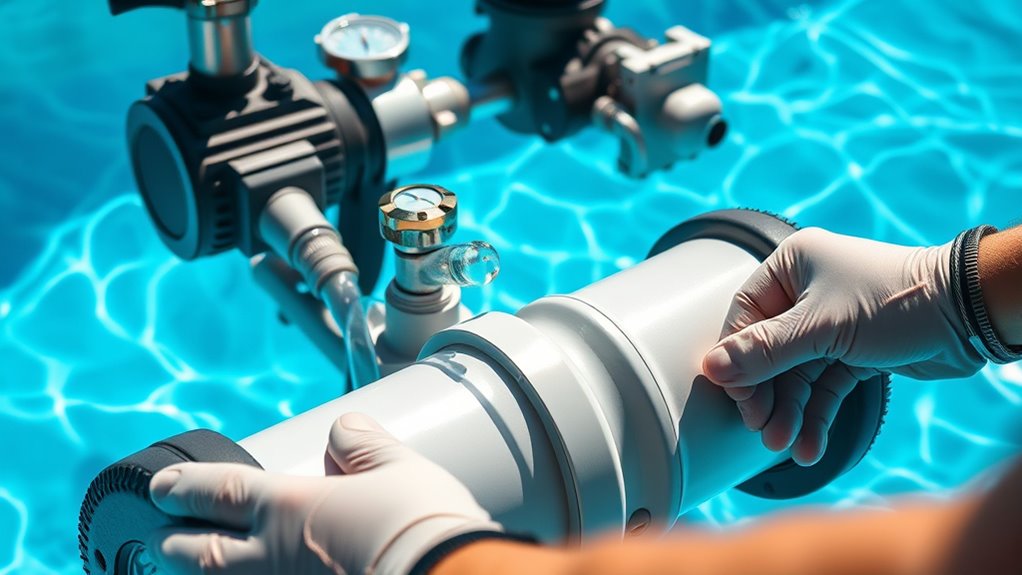

To guarantee your pressure pool cleaner operates effectively, you first need to check the water pressure and flow rate. Start by observing the pressure gauge on your pool’s filter system. It should read within the manufacturer’s recommended range—usually between 30 and 50 psi. If the pressure is too low, it indicates insufficient water flow, which can hinder cleaning performance. Conversely, if it’s too high, it may suggest a blockage or closed valve somewhere in the system. Next, check the water flow by observing the cleaner’s movement and water output. Adequate water flow ensures the cleaner moves smoothly and cleans properly. Adjust the valves or clean out any debris to optimize both water flow and pressure, ensuring your cleaner runs efficiently. Incorporating AI-driven data analytics can help monitor and optimize system performance for better maintenance and efficiency. Regularly inspecting system components like hoses and fittings can prevent pressure drops and ensure consistent operation, especially by checking for clogged filters that may affect water flow. Additionally, implementing smart monitoring systems can provide real-time alerts and detailed diagnostics to maintain optimal pressure and flow rates. To further improve system performance, consider filter cleaning routines that help maintain proper water flow and pressure levels.

Inspecting and Cleaning the Hoses and Connections

Since hoses and connections are critical for proper water flow, you should regularly inspect them for damage or leaks. Begin with hose inspection, checking for cracks, holes, or wear that could impair performance. Make sure hoses are securely attached to the pool cleaner and the pump, tightening connections as needed to prevent air leaks or water loss. Look for any loose or damaged fittings and replace or repair them promptly. Clear any debris or buildup inside the hoses to maintain ideal flow. Proper connection tightening ensures the system functions efficiently and reduces pressure loss. Additionally, proper maintenance of components such as hoses and fittings can help prevent mold and bacteria buildup, promoting a cleaner pool environment. Regularly inspecting your equipment also supports indoor air quality by preventing mold spores and bacteria from spreading through leaks or debris buildup. Checking for wear and tear on hoses and fittings can further prevent unexpected failures and costly repairs. Incorporating AI-powered diagnostics can assist in early detection of issues before they become severe. Performing routine visual inspections can help identify potential problems early, saving time and money. By routinely inspecting and cleaning the hoses and connections, you can prevent common issues that hinder your pool cleaner’s performance and extend its lifespan.

Examining the Pool Cleaner’s Skirt and Brushes

Start by inspecting the skirt seal to make sure it’s intact and not cracked or worn. Next, examine the brushes for any signs of damage or debris buildup that could hinder cleaning. Addressing these issues can improve your pool cleaner’s performance and prevent future problems. Additionally, ensure that the durability of the parts is maintained to withstand regular use and prevent sudden failures.

Inspect Skirt Seal Integrity

Inspecting the skirt seal and brushes is essential to guarantee your pool cleaner functions properly. A damaged or loose skirt seal can reduce suction and hinder movement, affecting cleaning efficiency. Perform an integrity check by examining the seal for cracks, tears, or deformation. If you notice any issues, replace the skirt seal promptly to restore peak performance. Regular inspections prevent bigger problems down the line and keep your cleaner running smoothly. Ensuring that the physical health of your equipment is maintained through such checks can prolong its lifespan and effectiveness, especially since projector technology relies heavily on proper component functioning. Monitoring the condition of the seal integrity helps maintain optimal suction and maneuverability. Additionally, staying informed about automation in business can inspire ways to incorporate similar efficiencies into your maintenance routines. Conducting routine preventive maintenance can further identify potential issues before they escalate, saving time and costs in the long run.

Check Brush Condition

Have you checked the condition of your pool cleaner’s brushes lately? Over time, brushes experience wear, reducing their effectiveness in cleaning your pool’s surfaces. Inspect the brushes for signs of brush wear, such as fraying, cracking, or missing bristles. If the brushes are considerably worn or damaged, they won’t scrub debris effectively, which can cause cleaning issues. In that case, consider brush replacement to restore peak performance. Regularly examining your pool cleaner’s brushes ensures they’re in good shape and working properly. Keep an eye out for uneven wear, which might indicate other problems like misalignment or debris buildup. Replacing worn brushes promptly helps maintain the pressure cleaner’s efficiency and prolongs its lifespan. Proper brush condition is key to a thorough and hassle-free cleaning experience.

Verifying Proper Installation and Positioning of the Cleaner

Ensuring your pressure pool cleaner is properly installed and positioned is essential for peak performance. Start by checking that the cleaner’s hose is securely connected to the pool’s return jet and that it has enough slack to move freely. Make sure the cleaner is evenly distributed across the pool surface, avoiding areas where pool chemicals or solar heating equipment might interfere. Proper placement prevents the cleaner from getting stuck or missing spots. Additionally, confirm that the cleaner is not obstructed by pool accessories or debris. Correct installation guarantees optimal water flow, which helps the cleaner operate efficiently. Proper water flow management is crucial for effective cleaning and to prevent the cleaner from stalling or missing spots. Remember, a well-positioned cleaner maximizes cleaning coverage and reduces wear and tear, keeping your pool clean and balanced without unnecessary strain on the system. Understanding the artistic significance of water and movement can also inspire better placement and operation of your cleaner for more effective results. Proper installation techniques are crucial to ensure the cleaner functions as intended and maintains long-term reliability, especially when considering the diverse outdoor equipment that might be present around your pool area. Additionally, paying attention to AI-driven insights can help optimize your cleaner’s positioning and maintenance routines for enhanced performance.

Ensuring the Filter and Skimmer Baskets Are Clean

Make sure to inspect your filter and skimmer baskets regularly to keep your pool cleaner running smoothly. If they’re clogged with debris, your pressure cleaner won’t work efficiently. Properly cleaning these baskets guarantees better circulation and reduces the chances of problems.

Regular Basket Inspection

Regularly inspecting the filter and skimmer baskets is essential for keeping your pressure pool cleaner working effectively. Good basket maintenance involves checking for debris buildup that can hinder water flow. Remove leaves, dirt, and other debris promptly to prevent clogs that may cause your cleaner to work harder or stop altogether. When inspecting, ensure the baskets are properly seated and free of obstructions. Consistent debris removal helps maintain ideal suction and prevents strain on your pool’s pump and cleaner. By staying vigilant with basket inspection, you reduce the risk of malfunctions and extend the lifespan of your equipment. Remember, a clean basket allows your pressure pool cleaner to operate smoothly, saving you time and effort in the long run.

Proper Basket Cleaning

To keep your pressure pool cleaner functioning smoothly, you need to clean the filter and skimmer baskets regularly. Clogged baskets can disrupt pool chemistry and hinder solar heating efficiency. Follow these steps:

- Turn off the pump and pressure cleaner to prevent water flow.

- Remove the baskets, checking for debris like leaves or dirt.

- Rinse baskets thoroughly with a hose, removing any stubborn grime.

- Inspect for cracks or damage and replace if necessary before reinstalling.

Regular cleaning ensures proper water flow, which maintains ideal pool chemistry and maximizes solar heating. Clean baskets also prevent debris buildup that can clog the system, reducing pressure and cleaning effectiveness. Keeping these components spotless helps your pressure cleaner operate efficiently and extends its lifespan.

Testing the Pump and Filter System

Before troubleshooting your pressure pool cleaner, it’s important to verify that the pump and filter system are functioning properly. Confirm the pump is running smoothly and the filter isn’t clogged, which can reduce water flow and pressure. Also, check your pool chemistry; imbalanced levels can affect the cleaner’s performance. Always follow safety precautions, like turning off the power before inspecting equipment. Use the table below to guide your checks:

| Step | What to Check | Why It Matters |

|---|---|---|

| 1 | Pump operation | Ensures proper water flow |

| 2 | Filter cleanliness | Prevents clogs and reduces pressure |

| 3 | Pool chemistry levels | Maintains ideal cleaning conditions |

Adjusting the Pressure Regulator or Valve Settings

If your pressure pool cleaner still isn’t performing properly after checking the pump and filter, adjusting the pressure regulator or valve settings can often improve water flow. Start by observing the pressure gauge to determine if pressure is too high or low. Then, follow these steps:

- Turn off the pool pump before making adjustments.

- Locate the valve or regulator connected to the cleaner’s hose.

- Use a wrench or your hands to perform a gentle valve adjustment, increasing or decreasing water flow.

- Check the pressure gauge again to ensure the pressure falls within the recommended range.

Proper valve adjustment ensures ideal water flow, helping your cleaner operate efficiently. Always make small adjustments and test performance before proceeding further.

Replacing Worn or Damaged Parts

Worn or damaged parts can considerably hinder your pressure pool cleaner’s performance, so inspecting and replacing them is crucial for peak operation. Over time, components like hoses, seals, or brushes may wear out or crack, reducing cleaning efficiency. Before replacing parts, ensure your pool’s chemical balance is proper, as imbalances can accelerate wear. If your pool uses solar heating, check that temperature levels are consistent, since temperature fluctuations can cause parts to expand or contract, leading to damage. Regularly inspect the cleaner’s components for cracks, tears, or corrosion. Replacing worn parts promptly restores suction and movement, helping the cleaner perform at its best. Keeping your pressure cleaner in good shape ensures energy efficiency and prolongs its lifespan.

Troubleshooting Common Mechanical Issues

Mechanical issues are among the most common problems that can disrupt your pressure pool cleaner’s performance. To troubleshoot, start by checking the pressure gauge calibration—an inaccurate reading can lead to improper operation. Next, inspect the hoses and connections for leaks or blockages that could hinder movement. Ensuring the chemical balance is correct is vital; imbalanced water can cause parts to corrode or stick. Finally, verify that the drive belts and wheels are intact and functioning smoothly. If your cleaner isn’t moving properly, these mechanical components might be worn or misaligned. Regularly inspecting these areas helps prevent breakdowns and keeps your cleaner running efficiently. Remember, addressing mechanical issues early saves time and prolongs your equipment’s lifespan.

Maintaining Regular Upkeep for Optimal Performance

Regular upkeep is essential to keep your pressure pool cleaner operating at its best. Consistently checking the chemical balance ensures your pool water stays clear and safe. Proper chemical levels help prevent algae growth, which can clog or impair your cleaner’s performance. Regularly test and adjust pH, chlorine, and algaecide levels to maintain ideal balance. Keep debris and dirt out of the pool, as they can strain the cleaner’s components. Rinse and inspect your pressure cleaner regularly, looking for signs of wear or damage. By maintaining these routines, you reduce the risk of mechanical issues and improve efficiency. Consistent upkeep minimizes maintenance costs and ensures your cleaner functions smoothly, providing a cleaner pool with less effort on your part.

Frequently Asked Questions

How Can I Tell if My Pressure Pool Cleaner Is Compatible With My Pool Type?

To ascertain if your pressure pool cleaner is suitable for your pool type, start by checking the pool size and the cleaner model. Make sure the cleaner’s recommended pool size matches yours, as larger pools may need more robust models. Review the cleaner’s specifications for your pool type—whether inground or above ground—and verify it’s designed for your pool’s surface. This helps you choose a compatible, efficient cleaner.

What Safety Precautions Should I Take Before Inspecting the Cleaner?

Think of safety precautions as your modern-day armor before inspecting your pressure pool cleaner. You should always wear safety gear like gloves and goggles to protect yourself. Confirm electrical safety by unplugging the unit and turning off the circuit breaker. Avoid water contact with electrical parts, and work in a dry area. Taking these steps keeps you safe and prevents accidents while inspecting or repairing your cleaner.

How Often Should I Replace Parts to Prevent Breakdowns?

You should follow a regular maintenance schedule to keep your pressure pool cleaner running smoothly. Replacement intervals vary depending on usage and part quality, but generally, you should inspect and replace brushes, hoses, and filters every 6 to 12 months. Regular check-ups help prevent breakdowns and extend your cleaner’s lifespan. By staying proactive with maintenance, you guarantee maximum performance and avoid unexpected repairs, saving you time and money.

Can Improper Pool Chemistry Affect the Cleaner’S Performance?

You might think improper pool chemistry doesn’t affect your cleaner, but it actually does. When the pool chemical balance is off, algae buildup can clog the cleaner’s filter and reduce suction, hampering performance. Additionally, imbalanced chemicals corrode parts over time. Regularly testing and adjusting your pool’s chemicals helps prevent these issues, ensuring your pressure pool cleaner runs efficiently and lasts longer. Keep the chemistry balanced for maximum cleaning results.

What Signs Indicate the Cleaner Needs Professional Repair?

When your pressure pool cleaner isn’t working properly, look for signs that indicate professional repair is needed. You might notice a leak detection issue, where water escapes from areas it shouldn’t, or hear unusual motor noise, like grinding or rattling sounds. These symptoms suggest internal damage or worn parts. If these signs persist despite basic troubleshooting, it’s time to call in a professional to inspect and repair your cleaner efficiently.

Conclusion

Did you know that regular maintenance can extend your pressure pool cleaner’s lifespan by up to 50%? By following these troubleshooting tips, you’ll keep your cleaner running smoothly and efficiently. Just a small investment of time can save you from costly repairs and downtime. Stay proactive with inspections and adjustments, and enjoy crystal-clear water all season long. Keep your pool pristine and hassle-free—your cleaner’s performance depends on it!