To maintain your booster pump, you should regularly inspect it for signs of wear, leaks, or corrosion, and keep an eye on vibration and noise levels. Clean or replace filters as needed, and monitor system pressure and performance to catch issues early. Lubricate moving parts and check electrical connections for safety and efficiency. Staying proactive with these steps helps prevent breakdowns and prolongs your pump’s lifespan—discover more tips to keep it running smoothly.

Key Takeaways

- Regularly inspect for vibrations, corrosion, leaks, and seal deterioration to identify early signs of wear.

- Clean or replace filters as needed to prevent strain and maintain optimal flow and pressure.

- Monitor pressure gauges and performance metrics to detect leaks, blockages, or system inefficiencies.

- Lubricate bearings and replace seals periodically to reduce wear and ensure smooth operation.

- Troubleshoot unusual noises and electrical issues promptly, and consider predictive maintenance for early fault detection.

Regular Inspection and Visual Checks

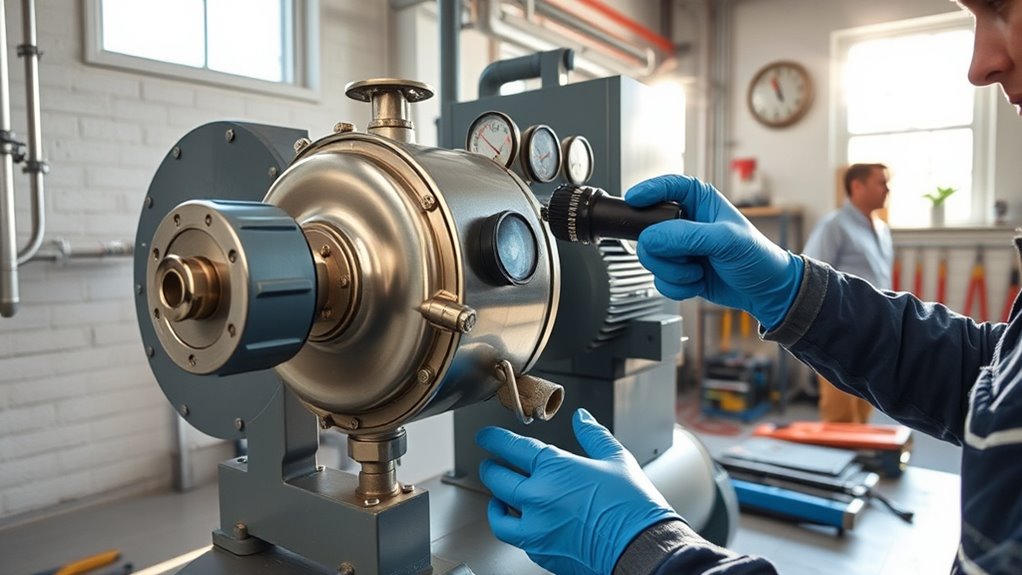

Regular inspection and visual checks are essential to guarantee your booster pump operates smoothly and efficiently. Start by observing for unusual vibrations, which can indicate misalignment or worn components. Vibration analysis helps you identify early signs of imbalance, preventing costly damage. Check for corrosion, especially on metal parts, as it can weaken the pump’s structure and lead to failure. Look for leaks, rust, or buildup that might compromise performance. Keep an eye on seals and connections for signs of deterioration. Regularly inspecting these elements allows you to catch issues early, reducing downtime and repair costs. Additionally, monitoring air quality around the pump can help detect any contaminants that might affect its operation. By staying vigilant with visual checks and vibration analysis, you maintain ideal operation and extend your booster pump’s lifespan, ensuring it continues to serve you reliably.

Cleaning and Replacing Filters

After completing visual checks, it’s time to focus on cleaning and replacing the filters. Regular filter maintenance is essential to keep your booster pump running efficiently. Start by turning off the pump and shutting the water supply. Remove the filter housing carefully, following your manufacturer’s replacement techniques. If the filter is reusable, rinse it thoroughly with clean water to remove debris and buildup. For disposable filters, replace them with the correct type and size, ensuring a secure fit. Check for any signs of damage or clogging, and don’t hesitate to replace filters more frequently if water quality is poor. Proper filter maintenance prevents strain on the pump, prolongs its lifespan, and maintains ideal performance. Incorporating high-quality filters can also enhance the overall efficiency of your airless paint sprayer system. Additionally, consulting filter maintenance guidelines can help ensure you’re following best practices for optimal operation. Regularly inspecting filters is especially important if you notice a decline in performance, which may be linked to issues like clogged filters that hinder flow and reduce efficiency.

Monitoring Pressure and Performance

Have you checked your booster pump’s pressure and performance lately? Regular monitoring is key to keeping your system running smoothly. Use pressure gauges to track pressure levels and guarantee they stay within the recommended range. Sudden drops or spikes can indicate issues like leaks or blockages. Pay attention to performance metrics such as flow rate and noise levels; changes here might signal declining efficiency. Keep a log of readings to spot patterns and identify early signs of trouble. Maintaining ideal pressure helps prevent pump strain and prolongs its lifespan. If your pressure readings are inconsistent or performance metrics fall outside normal parameters, it’s time to troubleshoot or seek professional help. Consistent monitoring ensures your booster pump operates reliably and efficiently. Additionally, understanding how to interpret juice extraction and other system metrics can help optimize your pump’s function and prevent potential issues. Regularly inspecting filter performance can also help detect airflow restrictions early.

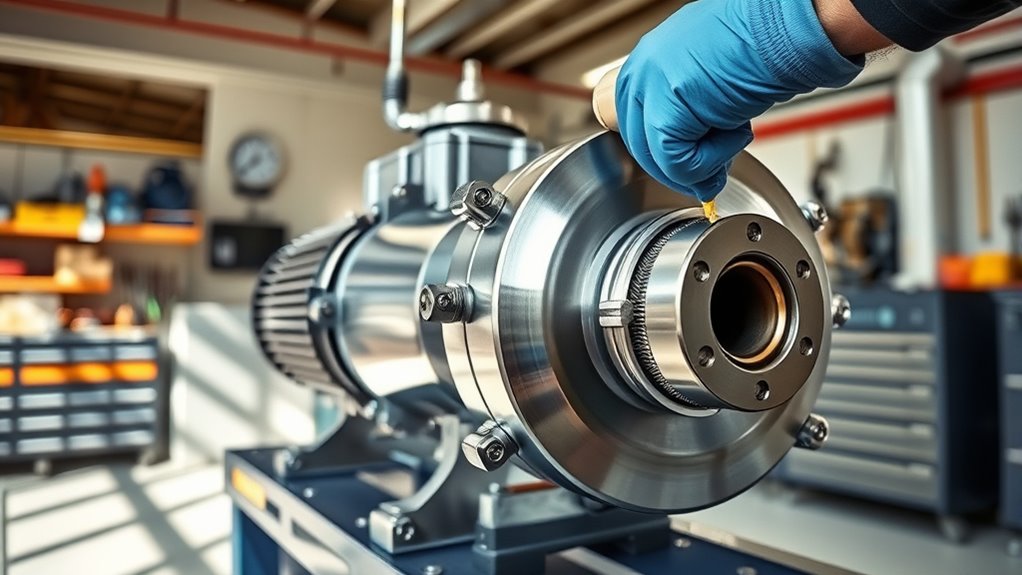

Lubrication and Mechanical Maintenance

Monitoring your booster pump’s pressure and performance helps catch issues early, but maintaining its mechanical condition is just as important for reliable operation. Regular seal replacement prevents leaks and maintains efficiency, while bearing lubrication reduces wear and prevents overheating. Keep an eye on moving parts and apply the correct lubricant at recommended intervals. Proper lubrication ensures smooth operation and extends component life. Additionally, understanding Gold IRA Rollovers can provide insight into diversifying your retirement investments for long-term security. Staying informed about industry innovations can also help optimize maintenance practices and improve equipment longevity, including advancements in maintenance technology that can streamline upkeep processes. Incorporating sound healing science principles, such as tuning frequencies during maintenance checks, can also promote better focus and precision in your work. Maintaining proper emotional alignment can also be crucial in ensuring the smooth functioning of complex systems, whether in machinery or personal relationships.

Troubleshooting Common Issues

When your booster pump isn’t performing as expected, quick troubleshooting can save time and prevent further damage. If you notice unusual pump noise, it might indicate cavitation, debris, or worn bearings. Check for any obstructions and ensure the pump is properly lubricated. If noise persists, inspect the electrical wiring for loose connections or corrosion, which can cause inconsistent operation or electrical faults. Turn off the power before inspecting wiring to avoid shocks. Also, verify that the electrical supply matches the pump’s specifications. If you find damaged wires or persistent issues after these checks, consider consulting a professional. Addressing pump noise and electrical wiring issues promptly helps keep your booster pump running smoothly and extends its lifespan. Regular maintenance routines that include checking for air leaks can also prevent performance issues. Incorporating industry transformations, such as AI automation, can also optimize maintenance routines and improve troubleshooting efficiency. Additionally, implementing predictive maintenance technologies can help detect potential problems before they lead to system failure.

Frequently Asked Questions

How Often Should I Schedule Professional Servicing for My Booster Pump?

You should schedule professional servicing for your booster pump based on its usage and manufacturer recommendations. An inspection schedule of at least once a year helps catch issues early. Regular troubleshooting tips, like checking for unusual noises or pressure drops, can prevent major problems. Staying proactive ensures your booster pump remains reliable, extends its lifespan, and maintains peak performance. Always consult your manual or a professional for personalized advice.

What Safety Precautions Should I Take During Maintenance?

Think of yourself as a guardian during maintenance. You should always wear personal protective equipment like gloves and safety goggles, like a knight donning armor. Prioritize electrical safety by turning off power and disconnecting the pump before working. Keep your workspace clear and follow manufacturer instructions to prevent accidents. These precautions protect you from hazards, ensuring your maintenance is safe and effective—just like a hero safeguarding their domain.

Can I Upgrade My Booster Pump for Better Efficiency?

Yes, you can upgrade your booster pump for better efficiency. Focus on increasing the pump capacity if your current system struggles to meet demand. Consider installation upgrades like advanced control systems or more energy-efficient models. Before upgrading, assess your current setup and consult with a professional to guarantee compatibility. An upgraded booster pump can save energy, reduce wear, and improve overall performance, making your system more reliable and cost-effective.

How Do Environmental Factors Affect Booster Pump Longevity?

Think of your booster pump as a hardy traveler facing nature’s challenges. Environmental factors like moisture and temperature impact its longevity, causing corrosion resistance to weaken and parts to wear faster. Extreme heat or cold accelerates deterioration, while humidity promotes rust. Protect your pump by keeping it in a controlled environment, ensuring it withstands these natural elements, and prolonging its life for reliable performance.

Are There Eco-Friendly or Energy-Saving Maintenance Options Available?

You can find eco-friendly or energy-saving maintenance options by choosing eco-friendly lubricants that reduce environmental impact and using energy-efficient parts to lower power consumption. Regularly inspecting your equipment helps identify areas where upgrades or adjustments can improve efficiency. Additionally, scheduling maintenance during off-peak hours minimizes energy use. These steps not only extend your booster pump’s life but also support sustainability and save you money over time.

Conclusion

By staying vigilant and performing regular maintenance, you keep your booster pump running smoothly. Check, clean, monitor, lubricate, and troubleshoot as needed—don’t let small issues become big problems. Remember, a stitch in time saves nine; taking care of your pump now prevents costly repairs later. Keep on top of maintenance, and your booster pump will serve you reliably for years to come. Stay proactive, and you’ll enjoy consistent performance every time.